Gas turbines are energetic power generating machine – able to convert heat crushed in the gas that enters the steam generator into electrical energy. There is a chance, however, that these machines will become damaged – and when this happens, it is crucial to find experts quickly. Having an emergency contact person not working with you 24/7 will be a great way of ensuring your turbine doesn’t malfunction.

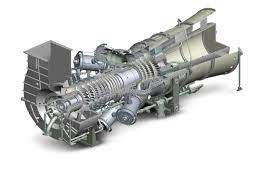

What is a Gas Turbine System?

Gas turbines are the most common type of turbomachinery used in power generation, and the type with which most readers are likely familiar. A gas turbine system (GTS) typically consists of four major components: the engine, compressor, combustion chamber, and spray nozzle.

The engine is a gas turbine that uses compression to accelerate combustion gases and turns them into high-velocity spouts that flow through the compressor. The compressor then takes these spouts and compresses them until the pressure becomes high enough to ignite the fuel mixture in the combustion chamber. The heat from thiscombustion process drives the turbine, which in turn powers the compressor and generates additional power.

A gas turbine system can be used to generate electricity or mechanical power. Electric generators use magnets to create an electric current, while mechanical generators use gears and other mechanisms to turn mechanical energy into electrical energy. Gas turbines can also be used to produce heat, water vapor, or air, among other things.

Gas turbines come in a variety of sizes and shapes for a variety of applications. Some common gas turbines include those used for aircraft propulsion,small ships and offshore oil drilling rigs, as well as power plants. Gas turbines

How to Avoid Main Turbine Component Failure

In order to keep your gas turbine running optimally, it is important to follow a few guidelines and some gas turbine repair solutions to help keep your turbines running smoothly:

– Regularly maintain your blades and other rotating components with a lubricant. This will help prevent them from becoming worn out and causing the main turbine components to fail.

– Regularly check the oil level in your main turbine engine (MTEE). If the oil level is too low, you may need to add more oil to the engine. Make sure you do this before large engines are operated for extended periods of time.

– Keep an eye on the rotor speed and adjust power output as needed in order to stabilize and protect the rotor blade system. Doing so will help reduce potential damage from high speeds or unexpected loads.

– Keep an updated log of all events that occur during turbine operation in order to identify potential issues and take corrective action as needed. ‘Document unusual noise levels, malfunctioning equipment, etc. This can help you identify any issues early and avoid costly repairs down the road.

Preventative Maintenance for Turbines

If you have a gas turbine, the only way to make sure it runs smoothly and efficiently is to regularly perform preventive maintenance. Here are three tips for ensuring your turbine stays in good shape:

1.Inspect engine seals and bearings for signs of wear. Replace items that show significant wear.

2.Check blades for nicks or damage, and replace them if necessary.

3.Clean and lubricate all moving parts as needed.

Troubleshooting Common Problems

Troubleshooting is key to preserving your investment in a gas turbine engine. This article offers tips and solutions to some common problems. Problems can arise with engines or components, so be persistent in seeking advice and solving the problem.

-Checking oil levels

-Performing scheduled inspections

-Detecting engine problems early

-Faulty air/fuel mixture

-Incorrectly set fuel injection parameters

-Gearbox problem

-Loose fan belt

-Excessive vibration

Conclusion

With the ever-growing demand for power, it is important that we take steps to maintain our gas turbines and other power-generating equipment.